A CNC punch press is an automated production machine used to form or punch predetermined shapes from thin stock material. CNC stands for Computer Numerical Control and refers to the computer programmes that control the machine's operating cycles. Most CNC punch presses are turret-type machines consisting of three basic assemblies: a powerful press turret, a main working bed that moves in two dimensions, and a set of controls that include a computer station. The process of punching material involves a workpiece, typically a thin sheet of metal, being moved into position under the press die along an X and Y axis by the computer program. With the workpiece in position, the programme tells it to move down the die and form or cut the desired shape and then return to repeat the cycle.

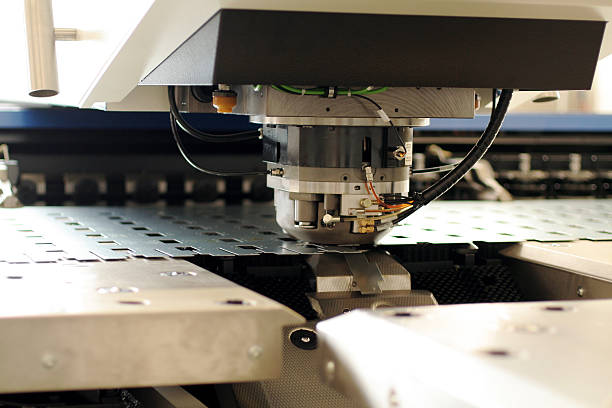

Electric punch presses are large machines, often used in industrial environments to create forms or to cut often complex shapes from thin stock. A CNC punch press is one such machine controlled by a computer with little operator input during the punching process. These machines usually have a turret design that includes a hydraulically operated wad and die set placed in a closed turret. A movable table or bed is positioned in front of and partly under the turret. This bed can move to feed workpieces along two axial planes (X and Y) or, in other words, forwards and backwards and side to side.

Both the bed and die set of the CNC punch press are controlled by a central computer, which converts a pre-loaded programme into sequential operations for both the die set and the working bed. In this way, the machine automatically advances the workpiece in a predetermined punch cycle pattern. This automated process is generally extremely precise and fast, providing excellent production rates and high levels of accuracy, with typical punch cycles measured in milliseconds. CNC punching is also economical, as the programme can reduce the minimum amount of waste or scrap generation from any workpiece.

The CNC punch press cycle consists of two basic parts - workpiece positioning and the actual punch cycle. Positioning places the workpiece exactly under the die set, and the punch cycle moves the die downward to cut or form the production part. After the cut or punch is made, the mould is moved up again, the workpiece is repositioned and the cycle repeats. When the cutouts are punched, the scrap produced falls into a collection bin for recycling. A CNC punch press not only allows for high production speeds and exceptional precision, but can also punch more complex shapes than other types of presses.