3d Scan

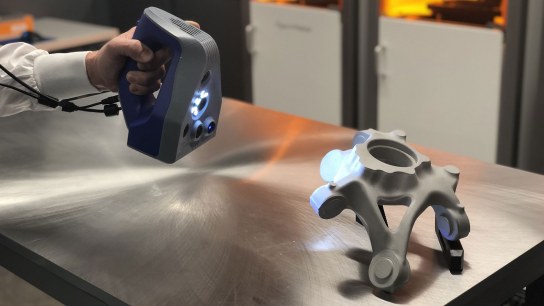

Reverse engineering is a powerful way to create digital designs from a physical part and is the most important step in prototyping, alongside technologies such as 3D scanning and 3D printing.Our 3D scanners measure complex objects very quickly and can greatly speed up your design workflow when it comes to real-life references. Thanks to the ability to capture and manipulate physical shapes, you can design 3D printed parts that fit perfectly into existing products of all kinds. 3D printed jigs allow you to reposition a drill or saw repeatedly or precisely join parts with glue. It creates well-fitting, reusable masks for sandblasting, painting or etching.

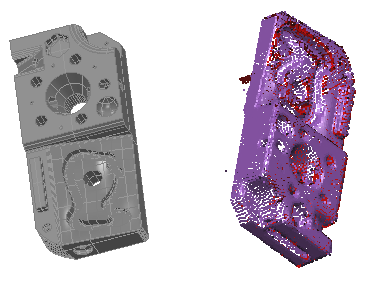

Laser 3D scanning is the most common and used 3D scanning technique. It digitally captures the shape of the object using laser light to obtain a digital representation of the real object. These 3D scanners can measure very fine details and capture amorphous shapes to create highly accurate point clouds. This laser scanning technique is perfect for measuring and inspecting complex geometries. It enables measurements and data to be obtained from places where conventional methods are impractical. A scanner using laser light is a bit like a camera, capturing only what is in its field of view. With this process, a laser dot or line is projected from the device onto an object and a sensor measures the distance to the surface of that object. This data is processed into a triangulated mesh and then into a CAD model.

To recreate an existing object, 3D scanning is a faster and easier technique for creating a 3D model for 3D printing. In a 3D model, changes can be added to it, so it is a great basis to start the project.